Maximize

Maximize

- Remove this product from my favorite's list.

- Add this product to my list of favorites.

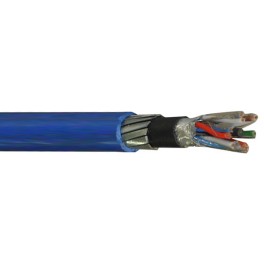

GM-MT/EPR/IND/SW4/GSWB/SW4 - EPR insulated, HFFR sheathed instrumentation cable (150-250 V)

GM-MT/EPR/IND/SW4/GSWB/SW4

150-250 V Construction

Conductor : tinned copper, stranded, class 2, for 1,5 mm²: 7x0,53 mm. Separator : MICA tape (fire proof). Insulation : EPR compound, 3G. Pair/Overall screen : screened by aluminium laminated polyester tape with stranded tinned copper drain wire (7x0,30 mm). Pair separator : polyester tape with numbered tapes 1,2,3...Separator : polyester tape. Armour : galvanized steel wires braiding, ~90% coverage. Separator : polyester tape. Inner/Outer sheath : cross-linked HFFR compound, SW4. Sheath colour : GM light blue. ** Other colours available upon request.

Conductor : tinned copper, stranded, class 2, for 1,5 mm²: 7x0,53 mm. Separator : MICA tape (fire proof). Insulation : EPR compound, 3G. Pair/Overall screen : screened by aluminium laminated polyester tape with stranded tinned copper drain wire (7x0,30 mm). Pair separator : polyester tape with numbered tapes 1,2,3...Separator : polyester tape. Armour : galvanized steel wires braiding, ~90% coverage. Separator : polyester tape. Inner/Outer sheath : cross-linked HFFR compound, SW4. Sheath colour : GM light blue. ** Other colours available upon request.